News

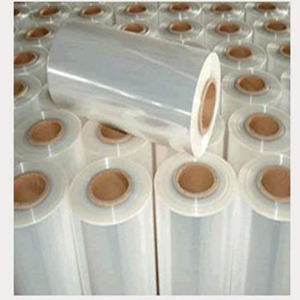

pallet stretch film manufacturers Production standards

pallet stretch film manufacturers Production standards for tensile winding film

1, no black impurities, mold must be cleaned, can not have burnt plastic fall into the naked eye can be found must be removed.

2, paper tube must be aligned, not one side and one side short. 1CM on both sides of the standard.

3. Pallet stretch film should pay attention to protect the edge when packing, do not collide, cause the edge crack to cause quality problems. There can't be a margin.

4, minimize the surface wrinkles at both ends and the white lines in the middle.

5, the pallet stretch film scrap must be cut and tidy. If the cut is uneven, it can not be shipped as finished products. Including the goods must be rolled up at both ends, no more here and less.

6, the thickness of pallet stretch film is uniform, and there is no 1MIC deviation.

Pallet stretch film has outstanding transparency, shortening and certain shortening stress, which allows customers to see the packaged goods directly and facilitate the customer to choose the goods. What is the effect of the tensile rate on the production of the winding film?

Pallet stretch film does not generally use longitudinal tensile, pallet stretch film tensile rate is a polymer limited by the use of copolymers or some metallocene PE mixed, because the wide molecular weight distribution makes it less tensile strength, the structure of the polymer will change, so the ultimate tensile rate, thus enhanced The properties of the winding film can open the air blowholes that give the product air permeability. These winding films are filled with calcium carbonate and other minerals. The film is cooled quickly by a cooling roll, after lengthwise stretching, and then further lengthwise stretching so that the polymer can be used. Separate from the filled mineral particles to achieve the effect of opening the air holes.

Pallet stretch film has high puncture resistance, which can protect goods and reduce damage during transportation.

The packaging of pallet stretch film must be directly stretched and pre stretched through stretching, tray mechanical packaging. Pre stretching is divided into two kinds, one is roller pre stretching, the other is electric stretching. The following two stretching methods are described as follows:

Direct tension is the end of stretching between the pallet and the membrane. This method is low in stretching ratio (about 15% to 20%). If the tensile ratio is over 55% ~ 60%, it goes beyond the original yield point of pallet stretch film, the width of the membrane is reduced, the puncture function is lost, and the membrane is easily broken. And at 60% elongation, the pulling force is still very large. For light goods, it is likely to deform the goods.

The pretension is finished by two rolls. The two roll pre - stretching rolls are connected by the gear unit. The drawing ratio can be different depending on the gear ratio. The tension is taken by the turntable, because the tension occurs in a short distance and the friction between the roll and the film is large, so the width of the film is not shrinking and the original puncture function of the film has been maintained. When the actual winding is not stretched, the cracking due to sharp edges or corners is reduced. This pre stretching can increase the tensile ratio to 110%.

The stretching mechanism of the electric pre stretching is different from that of the roller pre stretching. The two roller is electrically driven, and the drawing is completely independent of the rolling of the tray. Therefore, more adaptable, light, heavy, irregular goods are applicable, because the tension in the packaging is low, so this method of pretension ratio is up to 300%, greatly saving data and reducing cost. The proper thickness of the membrane is 15~24 m. LLDPE pallet stretch film is an industrial membrane product. It has high tensile strength, high elongation, good self adhesion and high visibility. Hand grade pallet stretch film can also be used for machine grade pallet stretch film, which can be widely used in all kinds of goods assembly packaging. Pallet stretch film, by virtue of the super strong coiling force and retraction of the film, bundled the goods into one unit in a compact and fixed way to make the scattered small pieces into a whole. Even in the case of bad luck, there was no slack and separation of the goods, and the pallet stretch film had no sharp edge and stickiness to avoid damage.

pallet stretch film